Nidaplast

Since its creation in 1984 in Thiante, near Valenciennes, France (59), nidaplast has been designing, manufacturing and selling its products, namely blocks and panels in extruded polypropylene honeycombs, for everyday use in industry, construction, civil engineering and the environment.

Nidaplast has demonstrated its ability to innovate and propose solutions for its construction, renovation and rehabilitation projects. Nidaplast has a wide range of lightweight, durable and effective products.

The thermoplastic honeycomb was created by combining materials (plastic) and structure (honeycomb) as part of an innovative research program in the 1980s, in order to obtain durable and very lightweight materials. The present invention was intended to open to a wider audience, a technology already used in the aerospace industry: honeycombs used in the core of structural panels. Nidaplast is proud to have initiated the integration of this technique into structures used in ships, buildings, industrial equipment, etc. Today Nidaplast has a return on investment of several million m2 of products sold worldwide and used as composite materials for lighting structures.

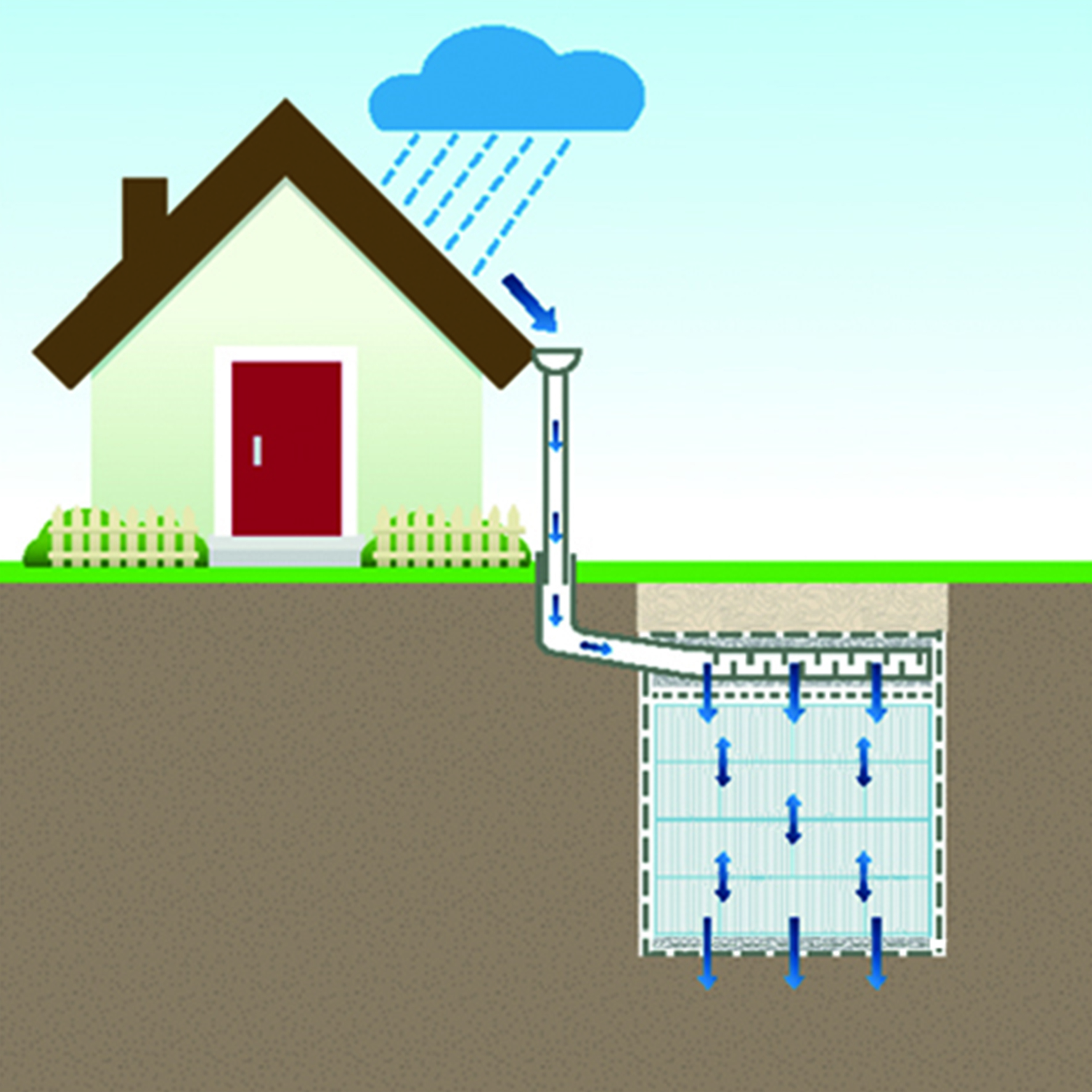

Polypropylene honeycombs very quickly showed their significant potential in other areas as well, especially in the form of cell blocks or slabs for rainwater retention, illuminated embankments, as well as for strengthening or stabilizing floors.

Product properties

- Optimal dimensions 1200 x 800 x 520 mm, eg 500 l per model

- A new benchmark for the application of alternative techniques

- maximum gap ratio (95%)

- Quick installation (easy transfer and cutting)

- Reduced operating costs

- Compression force 400 kPa

- Resistant to chemicals, microorganisms and mold

Product properties:

- Cleaning and self-cleaning modules

- maximum gap ratio (95%)

- wide range of compression force (400 – 600 kPa)

- Dimensions adjusted to site constraints

- fast laying (easy transfer and cutting)

- Resistant to chemicals, microorganisms and mold

- Reduced operating costs

Product properties:

- A module that can be monitored, inspected and high-pressure cleaned at all levels

- Maximum gap ratio (95%)

- high resistance

- quick lay

- Resistant to chemicals, microorganisms and mold

- optimal logistics